|

industrial IT > Production

Planning APS

Under the Opcenter brand, SIEMENS Digital Industries Software has created the most extensive, unique Manufacturing Operations Management (MOM) solution for production processes digitization (Industry 4.0), including the

Opcenter Advanced Planning and Scheduling (Opcenter APS) consists of 2 products:

ASKOM as the only certified SIEMENS partner in Poland offers a full portfolio of SIEMENS Opcenter MOM software, including the integrated

Opcenter APS system.

Global competition

The current trends in manufacturing are aimed at lowering inventory levels to reduce costs, while still being able to respond to shorter lead times and thereby satisfy customer demand. This forces companies to find ways to optimize production operations by reducing or eliminating nonvalue-added activities such as setup or waiting time. Highlighting potential problems allows action to be taken to balance demand and capacity.

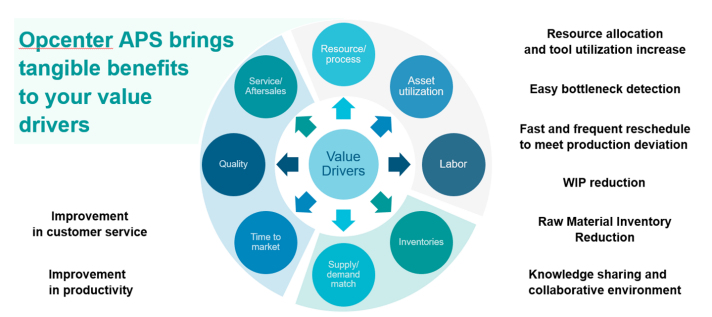

Opcenter APS products have been developed to meet this need. They are used by small and mid-size companies and large corporations to help meet demands made by their customers and beat the increasingly global competition.

Due to the flexible data model and scheduling logic, Opcenter APS products can be set up to meet a company’s planning and scheduling needs no matter what they are.

What about my existing software?

Opcenter APS products are designed to work alongside and facilitate, rather than replace, existing systems. They can be tightly integrated with enterprise resource planning (ERP), accounting and forecasting software, spreadsheets, manufacturing execution system (MES) and automation systems (SCADA).

Whether generating production plans that detail the task sequences for each resource by applying rules to load orders or producing long-term capacity plans, the products in the Opcenter APS range provide the interactive drag and-drop environment that modern businesses need in order to react efficiently to unexpected changes in demand and capacity and thereby maximize on-time deliveries.

How does Opcenter APS help lean initiatives?

Lean manufacturing is currently one of the industry buzzwords, and quite rightly so. Most companies are under

pressure to reduce costs while producing more and achieve shorter delivery times. All this has to be accomplished without an accurate indication of future demand and with lower inventories.

Lean manufacturing represents a cultural change at all levels of a company. Its prime objective is to eliminate waste in whatever form it takes. Independent international surveys, measuring on-time delivery performances and the improvement of throughput times, have proven that the most successful companies are those

using lean scheduling software, such as Opcenter APS. By connecting such systems to their ERP and shop floor data collection, these companies are able to monitor the state of execution against plan.

Visibility is key

You need to see the impact of your decisions. This cannot be achieved with more generalized tools, such as a

spreadsheet. Using Opcenter APS helps you to visualize the current load, see the impact of unexpected events, ask what-if questions and compare alternatives before the decision is made.

Who uses Opcenter APS?

Many companies, ranging from small and medium-sized businesses to

large corporations, employ Opcenter APS as part of their global

supply chain solution. These companies are located around the world.

The software’s flexibility means that it can be used by companies in

almost every sector of manufacturing, services and Logistics:

-

Automotive and aerospace

-

Chemicals and pharmaceuticals

-

Consumer packaged goods

-

Electronics and electrical equipment

-

Food and beverages

-

Furniture and wood products

-

Glass, ceramics and basic materials

-

Metals and metal fabricated products

-

Paper and packaging

-

Printing and publishing

-

Rubber and plastics

-

Textiles and apparel

-

Tooling and precision engineering

A complete family of solutions

Opcenter APS is not a single point solution. It represents a family

of products that, although based on the same

core code, have different levels of functionality and pricing so

that you can select the system that satisfies both your needs and

budget. Upgrading to another product as your needs change is simple

and easy.

Products from the Opcenter APS range can be used for long-term

strategic planning covering months and years ahead, medium-term

tactical planning with a few weeks planning horizon and for detailed

sequencing and scheduling.

Opcenter Scheduling - advanced scheduling

The Opcenter Scheduling (Opcenter SC) range has been redesigned to

introduce functionality that was previously only available at the

highest level throughout the range. All products in the Opcenter

Scheduling range are interactive, multi-constraint scheduling

systems. This means that the availability of resources and

additional constraints, such as tooling and materials, are all taken

into consideration during the scheduling process to ensure an

accurate model of your environment. Orders can be scheduled quickly

using intelligent built-in rules, and the planner also has the

ability to manually interact with the schedule to make changes based

on his or her experience or new information.

Opcenter Scheduling features a whole new level of software

customization, putting the power to change the way the system looks

directly into the user’s hands. This includes a new data editor grid

that allows custom sorts, filters and groupings to be applied and

enables the fields displayed to be selected while viewing the data.

In addition, there is a powerful table and field editor tool that

enables you to change the table and field names, redesign the

dialogs and set the display attributes of the fields.

Opcenter APS is

designed

to be easily integrated with other business systems to allow the

simple retrieval of any required data, be that work order

information from your ERP/MRP system or updates on operation

progress from an MES or Salesforce.com system. This is supported by

a simple, intuitive data exchange interface and a powerful workflow

tool that allows the rapid deployment of integrations. The

flexibility of Opcenter APS integration tools and data setup makes

it possible to implement the system entirely standalone, have it

fully populated by data from other business systems or any scenario

in-between. If information about product routings and BOMs is held

within Opcenter APS, then it is possible to use the system for ad

hoc order inquiries, allowing the planner to give accurate delivery

estimates in an instant.

Opcenter Planning - advanced planning

Opcenter Planning (Opcenter PL) general features Planning can be

executed in finite or infinite capacity mode and planning time

periods can be days, weeks, months or a combination of all three.

Parameters can be set against each item codes which allows different

calculations for each item. For example, some products may be in MTS

(Make-To-Stock) mode whilst others are in MTO (Make-To-Order) mode.

If used together with a Opcenter Scheduling system, detailed

production schedule information can be sent back to the planning

system and this will override planned volume with scheduled volume.

MPS can then be re-calculated using production schedule as the base

for new results.

Opcenter Planning make-to-stock In the food, drink, consumer goods

or similar sectors, it is quite likely that

production process is in MTS (Make-To-Stock)

mode, in which case the primary driver in creating the MPS will

typically be forecast of future demand. Opcenter Planning imports

current stock levels plus actual and forecast

demand. It then considers rough cut capacity,

pack forward figures, target days of stock cover, manufacturing

preferences, minimum/maximum reorder quantities,

re-order multiples, product shelf life, etc. to propose an accurate

and achievable MPS. Production capacity can be specified as a

quantity, duration or weight and using the

Opcenter APS calendar system capacity can be varied over time. The

capacity available then limits the production volume created in each

period. Once an initial MPS has been created, the data can be

displayed as both stock profile graphs and capacity usage graphs.

The MPS can be changed by simply clicking and dragging a point on

the stock or capacity graphs, and the production of a particular

item can be moved from one planning period to another. Any changes

made will be reflected in all the linked plot and grid windows. The

planning BoM can also be exploded by Opcenter Planning and then the

production plan for lower level items is

calculated in the same way. Based on the BoM explosion and the

production plan, the proposed material purchase requirements can be

exported to an ERP system, Excel, etc. for action.

In a MTO environment, the stock levels of

finished and/or intermediate items will not be part of the key

process parameters, but there will still be the need to evaluate the

effects of future demand changes on the manufacturing process. For

example, for complex assemblies in the aerospace sector, each

finished item may have a deep BoM (Bill of Materials) and be made up

of thousands of individual components. Many of those components are

manufactured in-house and they share production capacity, so there

is a complex relationship between

manufacturing capacity and demand. When a change in demand occurs,

whether that be in terms of quantity or delivery dates, there is a

need to be able to quickly assess if it is possible to meet the new

requirements.

It is possible to import demand changes into Opcenter Planning and

create a new ‘what if’ plan. The planning BoM will be exploded and

Opcenter Planning will show if there are any capacity issues. If

there are issues, an acceptable MPS can be created by working

interactively.

Customization

Opcenter APS is a highly customizable capacity

planning and scheduling package. Fields and data tables in its

Microsoft® SQL database can be added or changed.

Unique sequencing rules can be created. Event-driven communication

scripts can be installed for tight integration with other systems

across multiple sites. Its flexibility is unparalleled.

Both the planning and scheduling products can be

configured in a number of different ways. Often, users have a single

master system that communicates with one or more Opcenter APS

Viewers to share schedule information. Conversely, other companies

employ multiple licenses across one or more departments, units or

plants, with an automatic transfer of information from one system to

another.

***

Download brochures:

Opcenter Advanced Planning and Scheduling

download

Format: PDF (1,04 MB)

Format: PDF (1,04 MB)

Opcenter

APS Food Sector

download

Format: PDF (1,29 MB)

Format: PDF (1,29 MB)

Opcenter

APS Packaging Sector

download

Format: PDF (1,25 MB)

Format: PDF (1,25 MB)

Opcenter

APS Pharmaceutical Sector

download

Format: PDF (1,14 MB)

Format: PDF (1,14 MB)

Opcenter APS screenshots:

go up

back

|