|

|

industrial IT > Production Process Visualization

MES + SCADA

The industrial IT systems offered by ASKOM are always tailored to the

Customers' possibilities and specific requirements. Almost from the

start of our business, we have offered dedicated IT solutions developed

at the Customer's request and based on previously prepared

specifications of business requirements and needs or as extension to

existing automation systems. These systems are mostly addressed to

Polish production companies (but we also have carried out

implementations in the Polish plants of international concerns) and to

implement them we use our own product: the SCADA Asix system (www.asix.com.pl/EN/).

Asix SCADA

Asix in addition to standard visualization and control, it allows

effective data logging, reporting and generating of graphical trends,

alarms management, creating recipes, process visualization on Internet,

multilanguage support, production monitoring and tracking. All this is

available through scalable licensing policy to match the size of the

project.

More than 13 000 user licenses are an impressive achievement, which

confirms the many strengths of Asix when successfully applied in various

demanding fields, such as:

-

food industry,

-

chemical and mechanical industry,

-

automotive industry,

-

steel industry, power generation and heating, coking plants,

-

public utilities, smart buildings and telemetry systems.

Historically developed and offered in the market as a SCADA / HMI

visualisation package, Asix has now many features to allow for its

employment in applications for monitoring the consumption of energy

utilities or the efficiency of machines that are already typical

applications which carry out the functionalities of MES-class production

management systems:

Recipe management and production tracking & tracing

The standard Asix package includes AsBase, a specialized tool for

database maintenance, which is compatible with Microsoft SQL Server (also

in a free Express version). It allows you to easily apply the recipes

both in manual and automatic mode. Recipes are supported by the

application using standard actions and visualisation objects, which

means that the operator does not have to learn new control methods or

the complex database utilities interface.

In addition to recipe support, AsBase offers manual or automatic

registration of predefined data records which contain selected

technological process parameters associated with a specific product or

batch through a unique identifier. This allows production flow tracking

and generating production documentation for a single product or product

batch. Such product history is often required for formal reasons in

order to make the product identifiable and ensure its quality and is

often the basis of production management analysis.

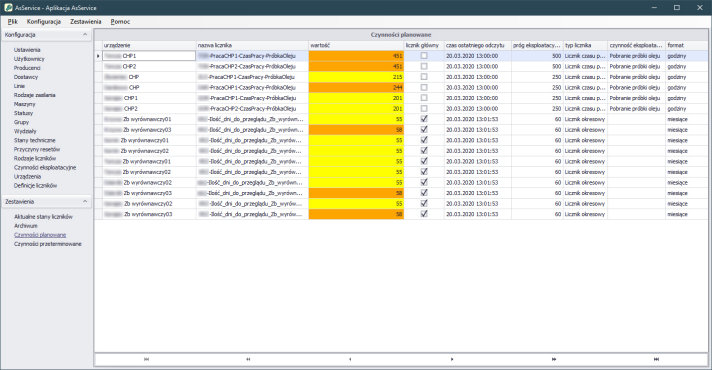

Manufacturing assets management

Optimum utilization of production resources requires the availability of

information about resources and statistics how they are used. Based on

data collected from Asix application, the new AsService module can log

the operation times and the number of times the devices are switched

on-off. This makes possible to alert the user to carry out the necessary

maintenance and repair operations and report any missed maintenance and

log the related technical data for each monitored device. The AsService

module manages asset (equipment and machinery) database which allows you

to collect and properly group data pertaining to all devices. All

information generated and processed by the AsService module (meter

readings, maintenance operations, history of operations, ...) is related

to the equipment specified in the database. For each device, it is

possible to define a set of electronic documents associated with its

operation, such as operation and maintenance manual, operating

instructions, test protocols, flow charts, and other documents.

Maintenance support

Supervisory personnel often work in a tour of duty system and they do

not have to be present on site all the time. However, they need to be

reliably and promptly notified of any system abnormal operation or

failure. AsAlert module offers this functionality in a smart way — the

list of alert message recipients and the messaging schedule ensures that

appropriate information reaches the relevant personnel at the given

time. Messages can reach recipients in a variety of ways:

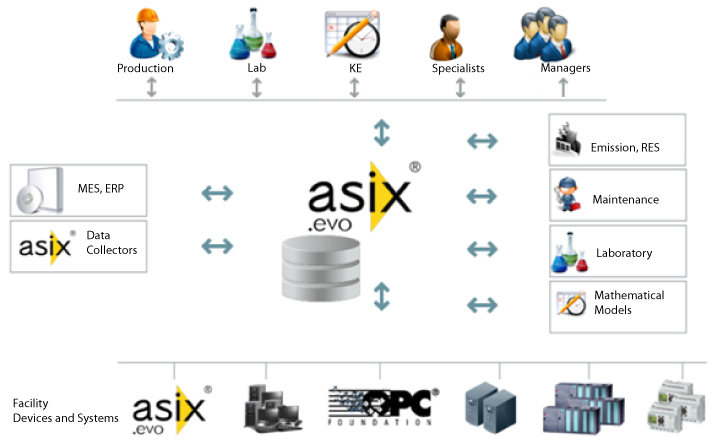

Przemysłowa szyna danych IT/OT pomiędzy systemami IT i automatyk±

Industrial IT / OT data bus between IT and automation systems

A wide range of communication protocols available in the Asix package

enables the use as an IT / OT data bus, ensuring communication between

automation systems (e.g. PLC, HMI, SCADA, DCS) and IT systems (MES / MOM)

and cloud solutions.

Raw

and pre-processed production data and machine resource data is usually

required at higher management levels. Specialized MES/MOM and ERP

systems must be fed with the production data. Asix is a natural tool for

this purpose – it has all the information, pre-processed data and

analysis results. Asix may share such data with the use of standard OPC

/ OLE Automation /.Net / REST mechanisms or using other selected format.

With such a link, the data is coherent at all levels, and its delivery

to the higher levels in the management hierarchy is facilitated.

ASIX as a platform for custom solutions

The wide range of functionalities, openness and scalability of the Asix

system enable the creation of specialized applications, providing

solutions to even very complex tasks set by customers. The use of Asix

functionality is available through a programming interface (API), which

enables the launch of external libraries with specialist technological

knowledge, having complex algorithms, mathematical models, or elements

of artificial intelligence - e.g. neural networks. The solution on the

Asix platform allows programmers to focus only on specific

functionalities, while ensuring protection of intellectual property

Currently, Asix is being used in many applications as a system platform,

both for individual solutions aimed at the requirements of a specific

customer, as well as in extensive products widely available on the

market, such as:

-

Asix Energy - Energy Management System (EMS) used to monitor

consumption of any energy media, such as: electricity, gas, heat,

compressed air, water, waste water, etc. It clearly presents measured

and processed data, supporting the process of taking strategic decisions

aimed at optimizing production costs. […]

-

Asix OEE - a system for monitoring the efficiency of machines,

production lines and entire plants. Assessing the productivity of

machines and the number, duration and root causes of downtime, and hence

losses, is the key to improving the competitiveness of manufacturing

companies.

-

Asix CDAS - a comprehensive Central Data Acquisition System (CDAS)

that enables reading, archiving, presentation and reporting of data from

multiple sources (also other than Asix), which integrates various

industrial environments and IT systems.

-

WAGO Visu Building - a modern Building Management System (BMS)

offered by WAGO.

***

Asix.Evo -

leaflet

download

Format: PDF (54,6 MB)

Format: PDF (54,6 MB)

Asix.Evo -

technical specification

download

Format: PDF (1,58 MB)

Format: PDF (1,58 MB)

go up

back

|

|